Prototyping Fails Happen to Everyone

My boss took my design, chucked it in a vice, and then took one decisive swing at it with a rubber mallet.

More accurately, my boss’ boss. I’d challenged a colleague to break a peg that I have been iterating on, and the department director wanted to take a literal swing at it.

Every prototype has failed so far, and for various reasons.

At the Fayetteville Public Library, in the Center For Innovation, and inside the center’s Photography Studio, we have an background support system. It is one of the assets that make available, or at least try to, for patrons to use. The system is useful for hanging backdrops.

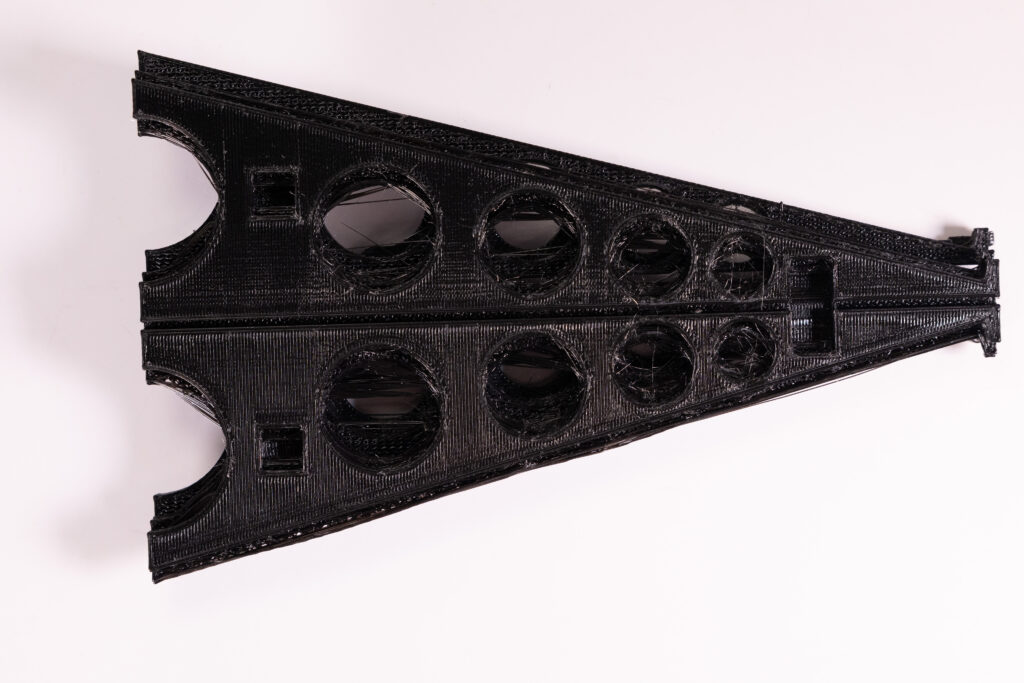

The system is simple: two tripods and a horizontal bar. The tripods are supposed to have two pegs that nest inside the horizontal bar. Someone—we suspect a ne’er-do-well—pilfered the pegs.

I have been, since then, trying to design and iterate on that a 3D-printed replacement with very limited success.

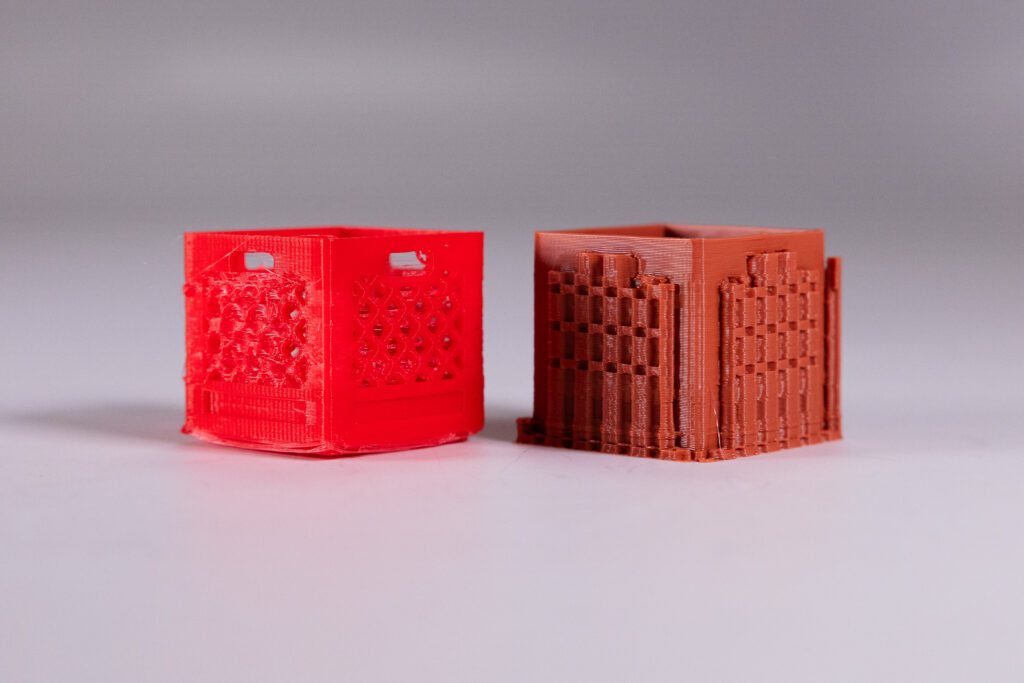

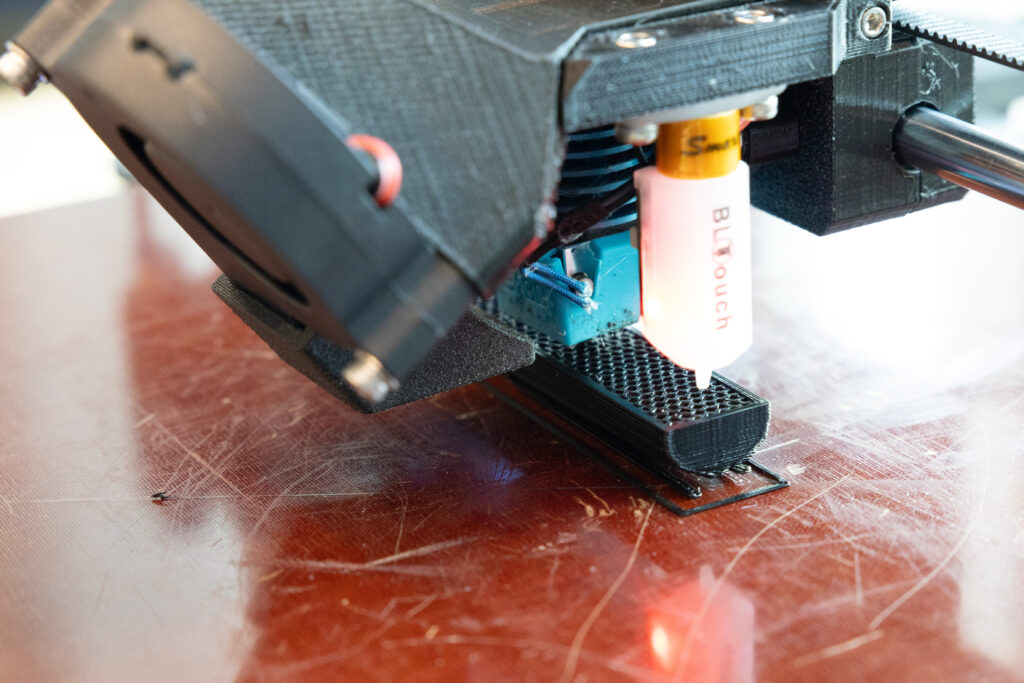

There were a variety of failures on the print bed that occurred while we tuned our 3D printers. The first completed print crumbled; the infill setting was too low. One peg sheered in half in the tripod, but it lived long enough for a patron to finish their photoshoot.

I tried drilling a wood screw through the peg, but I apparently cannot drill straight. In fact, I drilled through the sidewall. The department director smashed my latest iteration with a hammer.

Back to the drawing board, at least while we await replacement pegs to be sent from the manufacturer.

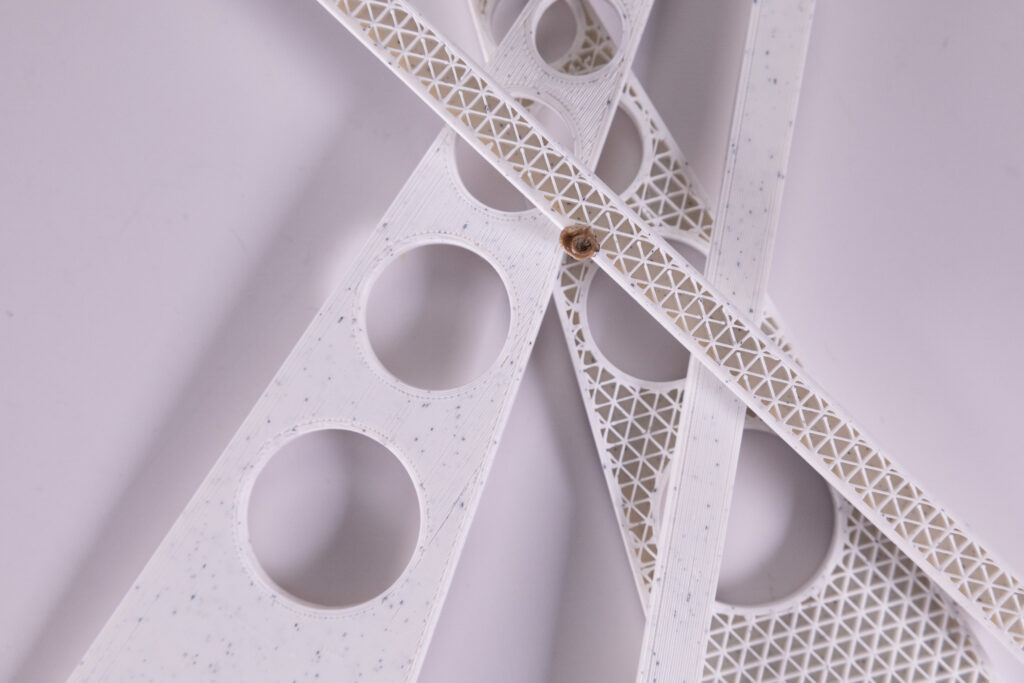

Part of what makes prototyping in a maker space, such as the CFI, useful is that I have been able to share my failures with diverse peoples. In turn, they have been able to share advice and knowledge for my next iteration. It has allowed me to quickly create and test ideas before investing a lot of time and money.

While 3D printing replacement pegs is not most efficient way to solve this problem, it has enabled me to engage in the prototyping process.

Failure is an integral part of that process. Prototyping is about testing, refining ideas. It is about trying things to see what does and does not work.